Business introduction

Plastic Product Manufacturing

From planning to model making, mold manufacturing, molding, secondary processing (printing, welding, etc.), assembly and packaging, while taking advantage of our ability to carry out integrated production in-house, we manufacture and sell various household items, mainly kitchen items made primarily of plastics.

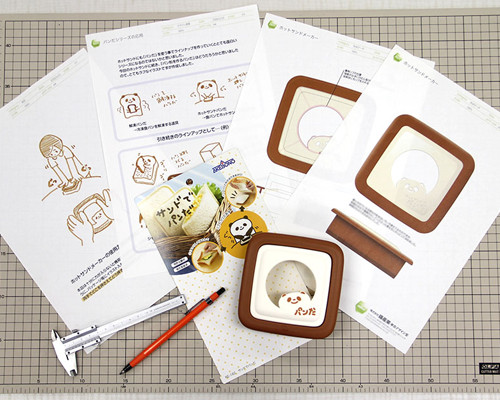

Planning / Design

Our employees themselves come up with ideas based on what they feel and notice in their daily lives, and work on planning and design while valuing a momentary flash of inspiration above all.

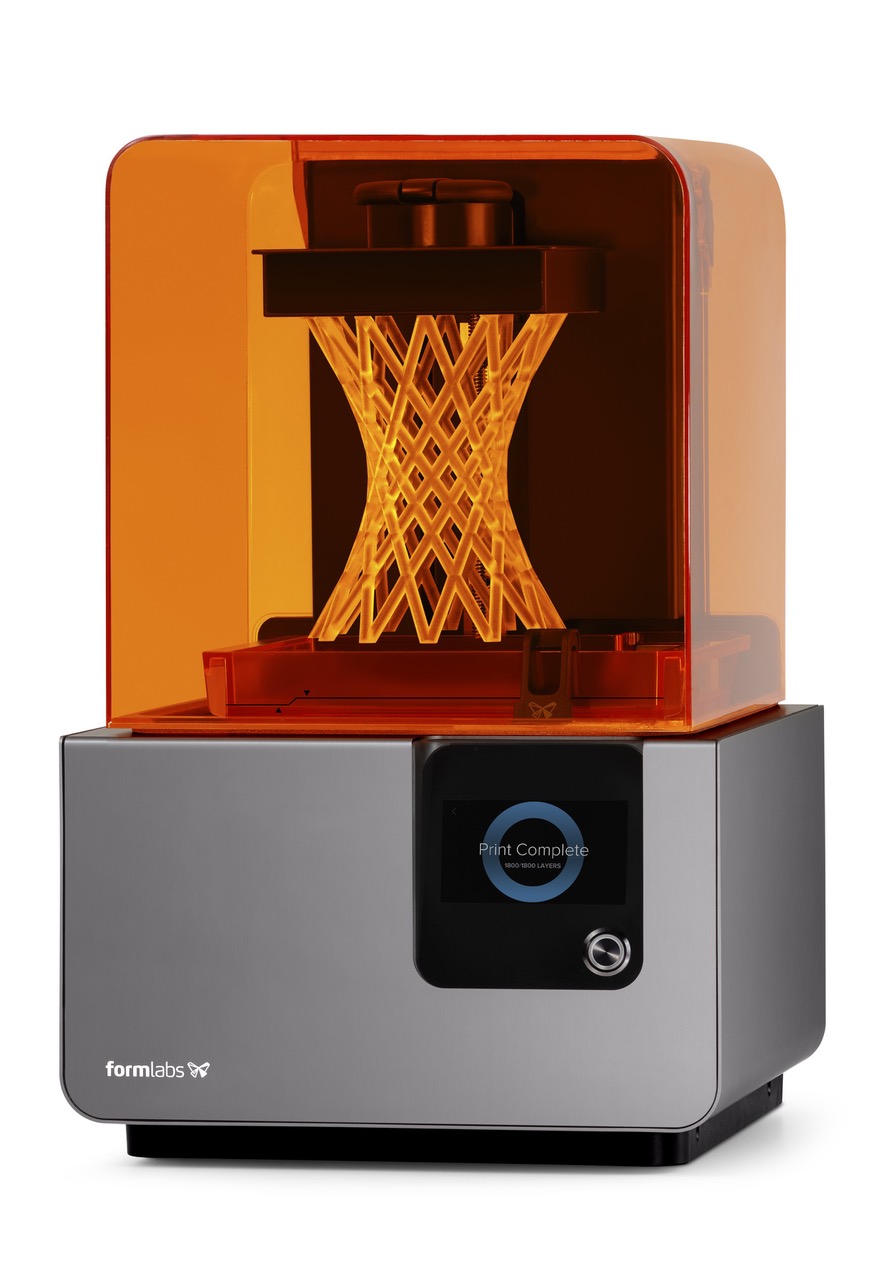

Model Making

We have a machining center for 3D printers and cutting model production. For cutting models in particular, they can be verified using the same plastic as the actual product prior to manufacturing the mold, so this makes it possible to perform accurate product testing and engage in difficult product manufacturing.

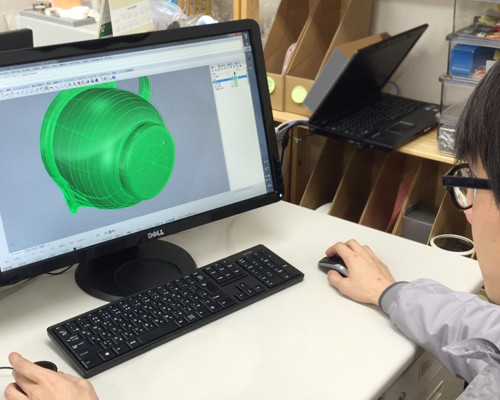

FreeForm (Modeling software)

The ultimate modeling tool that directly expresses the image of the designers and creators without waste. You can model while actually experiencing the sensation of "touch" transmitted through the "Phantom" 3D mouse.

3D scanner

A non-contact 3D scanner equipped with a high-resolution twin CCD camera. Easy to operate and capable of high-speed, high-quality data acquisition. It accelerates the speed of development.

| Owned Equipment |

|---|

| Small machining center for model cutting (FANUC) |

| FDM 3D printer (Mutoh Engineering) |

| FDM 3D printer (L-DEVO) |

| Non-contact 3D scanner |

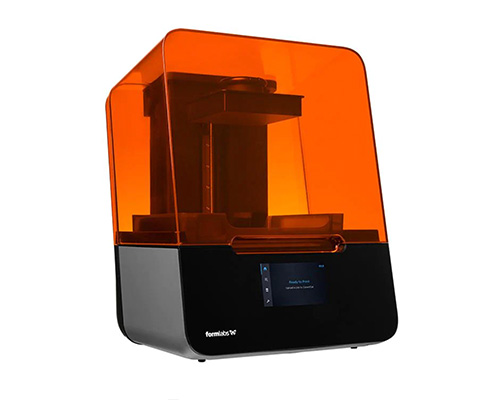

| Stereolithography machine (form2) |

| 3D CAD (freeform PHANTOM) |

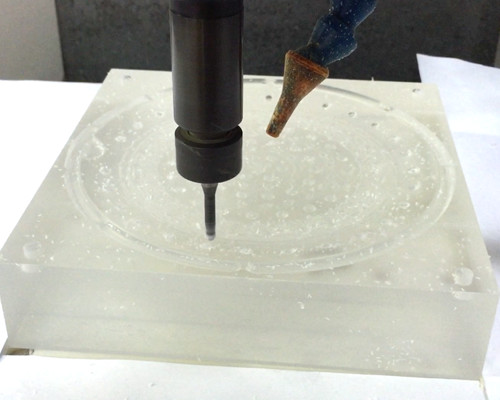

The fusion of cutting-edge machines and delicate hand-crafted technology makes speedy and high-quality mold manufacturing possible.

High-speed machining center

In recent years, there has been increased complexity of mold structures, demand for high precision and short delivery times and an increase in difficult-to-cut materials. We have a "high-speed, high-precision machining system" with high-speed high-precision processing machines that have high-speed rotation spindles and achieve high-speed feed rates, and CAD/CAM systems that drive them with high reliability.

| Owned Equipment |

|---|

| 2D CAD |

| 3D CAD / CAM |

| High-speed machining center |

| Machining Center |

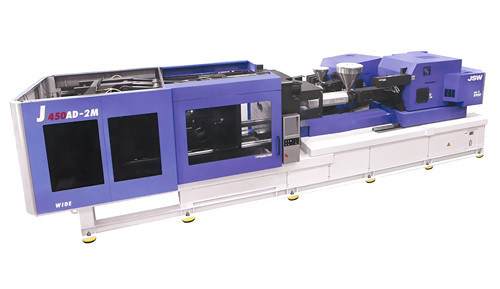

Molding

While making the best use of the molding technology we have cultivated over many years, we have established a system that can respond to the recent demand for high-mix, low-volume production. We also have a special class plastic molding technician as the leader of the department.

Injection Molding Machines (Injection)

We have installed the J-AD series of JSW Japan Steel Works, and we perform plastic molding using an all-electric injection molding machine, in pursuit of high-speed, high-quality, high-precision technology.

Plastic molding technician

The plastic molding technical skill test is "a system that aims to further develop the skills and improve the social and economic status of technicians by testing the degree of skill they possess according to a certain standard and having it certified by the national government." Technicians who have passed the test play an active role as leaders in the production department, and passing the test is highly rated in the workplace as proof of a reliable technician.

DSI molding

DSI molding (Die-Slide Injection molding) is a new molding technology for injection molding of hollow bodies and laminated structures. It makes it possible to accurately and speedily mold hollow bodies with complicated internal structures.

| Owned Equipment | |

|---|---|

| Injection molding machine (electric) 55-450 tons (Japan Steel Works, Niigata Machine Techno and others) | 18 units |

| Injection molding machine 180-350 tons (Japan Steel Works, Niigata Machine Techno and others) | 5 units |

| DSI 2-color molding machine 180-450 tons (Japan Steel Works) | 2 units |

| Automatic extractor, 7-axis servo 5 units Automatic extractor, 5-axis servo 18 units (Star Seiki and others) |

23 units |

| Employed molding technicians | |

|---|---|

| Special class molding technician | 1 |

| Molding technician 1st Class | 3 |

| Molding technician 2nd Class | 3 |

Secondary Processing

Secondary processing is performed on plastic parts after molding. By carrying out a wide range of secondary processing in-house, Akebono Industry achieves stable quality, shortened delivery times, and cost reduction.

Welding

We firmly attach plastic parts to each other without the use of chemicals such as adhesives.

| Owned Equipment | |

|---|---|

| Ultrasonic welder 1200 type 4 units Ultrasonic welder 2100 type 5 units (Seidensha Electronics) |

9 units |

| High frequency welder 10K (Seidensha Electronics) | 1 units |

We print lettering, patterns and illustrations on the surface of plastics.

| Owned Equipment | |

|---|---|

| Screen printing machines: flat-surface machines, curved-surface machines (Shin Ei Industry and others) | 4 units |

| Pad printing machines: 1-color machine, 2-color machine (Navitas) | 2 units |

| Plate making machines for silk printing | 1 units |

| Corona discharger (Kasuga Denki) | 2 units |

| Roll transfer machine (Navitas) | 1 units |

Pad Printing

Pad Printing Screen Printing

Screen Printing

Assembly and Packaging / Miscellaneous

We carry out work meticulously, right up to inspection, assembly, and packaging, according to a manual.

| Owned Equipment | |

|---|---|

| Assembly lines A to F | 6 lines |

Efforts for quality stability and management

We are equipped with facilities for product quality stability and management. We also carry out advanced analysis and research in collaboration with various industrial laboratories in the prefecture, food research centers, and engineers. In addition, as a pioneer of plastic microwave oven cooking products, we have a large number of microwave ovens from various manufacturers for use in experiments.

Utilization of intellectual property rights and efforts to protect those rights

As a manufacturer that plans, designs, and manufactures our own original products, we strive to make effective use of intellectual property rights. We hold and utilize a large number of patents, utility models, design rights, and trademark rights, including our leading patented technology -- double embossing. In addition, we strive to protect these rights, by taking strict measures against manufacturers of counterfeit products, together with our advisory patent attorneys and legal counselors.

OEM manufacturing

We also handle development of products according to customer specifications (OEM products). Utilizing our proprietary technologies cultivated over many years, we develop, design and manufacture various items, from parts to finished products. We have more than 40 years of experience in OEM manufacturing. We can flexibly accommodate everything from small lots to large-volume orders. Please feel free to contact us for more details.

| Owned Equipment | |

|---|---|

| Thermostatic chamber | 1 unit |

| Microwave ovens | 30 unit |

| Microscopes | 3 unit |

| Infrared thermometer | 1 unit |